Pressure Die Casting

CasterMetal offers innovative ways to give you metal casting and other products. Weassure you an optimized supply chain from tools/equipment to quality wedges,stainless steel, and more.

CasterMetal has topnotch and affordable procedures in the castings field. Our teamguarantees that we meet our client’s strict criteria. Hence, you’ll achievebusiness growth through the metals and services we offer.

InCaster Metal, you have a creative and cost reduction to the needs of yourbusiness. One of the ways we do this is through our effective manufacturingprocedures such as pressure die casting, for example. Our engineers are skilledand trained to perform any manufacturing process.

Onthis page, we’ll focus on pressure die casting that we’re proud to introduce toyou.

What isPressure Die Casting?

CasterMetal offers pressure die casting as a fast, cost-effective, and reliablemanufacturing process in producing high volume of metal components. (Thesemetals are net-shaped and have tight tolerances.)

Weinject a molten metal alloy on a steel mold or tool. The molten solidifies to form the net-shapecomponent. (The solidification process happens from milliseconds to seconds.)Then, we extract the metal automatically.

Here in Caster Metal, we use two different pressure die casting types– high and low pressure die casting. Highpressure die casting offers a huge application that covers 50% of light alloy.Meanwhile, low pressure die casting covers 20% of the total alloy production.

If you need castings having detailed geometry and tight tolerance,high pressure die casting is the ideal procedure we use. We perform low pressuredie casting for large non-critical metal parts.

HighPressure Die Casting

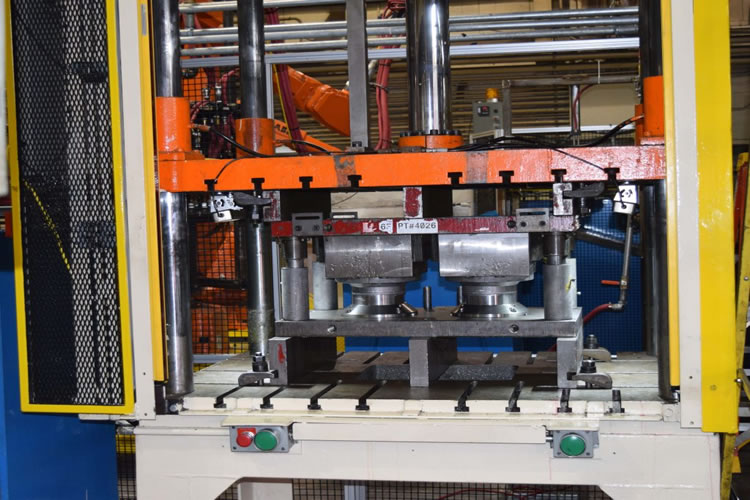

With this process, we inject high speed and pressure to the metalmold. The basic equipment we’re using is two vertical platens. We placebolsters in the platens that hold the die halves. (One of these platens aremovable, and the other is fixed.)

Because of this, the die can open or close. Then, we pour a specificmetal in the shot sleeve that goes to the mold cavity. We perform the processusing a hydraulic-driven piston. Once the metal solidifies, we open the die andremove the casting.

LowPressure Die Casting

We produce high-quality alloys and magnesium through low pressure diecasting. We offer aluminum casting using this process.

Here’s how we do this: we position a metal die above our sealedfurnace that contains molten metal. (A riser extends from the die’s bottom intothe molten metal.) Then, we introduce low pressure air inside the furnace.

Next, the molten metal rises up the tube and enters the die cavity.After the metal solidifies, we release the air pressure. The metal is still inmolten state inside the riser tube and falls back to the furnace.

Take note: Machines and die areexpensive, so pressure die casting is ideal for high metal production.

PressureDie Casting Advantages

CasterMetal is proud to perform pressure die casting to create different alloys. Ourteam makes sure to achieve a successful die casting process. With ourinnovative approach and expertise, we guarantee you would achieve excellentwork and satisfaction.

Also,you would be glad to know the benefits of pressure die casting, such as:

- Lower cost than other processes

- Economical for companies andbusinesses

- The castings are lightweight

- Excellent surface finish anddimensional control

Caster Metal makes sure that you would haveand experience these advantages when you contact us. We’re ready to listen tothe specifications you need for your business. Our engineers are ready to giveexcellent and reliable service anytime.

Pressuredie casting is ideal for the following:

- Kitchenware (for example pressure cooker)

- Aerospace castings

- Automotive parts (such as blocks, wheels, cylinder heads, manifoldsand more)

- Cabinets perfect for the electronic industry

- Electric motor castings

- General hardware appliances

CasterMetal is here to help you reach your business goals. With our insight andexcellent approach, we guarantee that our services are high-quality. Our teamis ready to listen to your needs, whether you like alloys or other services.

Throughour cost-effective pressure die casting process, you gain satisfaction you aimfor your business. We have large resources and materials to ensure our pressuredie casting procedure is effective. Come now and try our services!