Gravity Die Casting

Caster Metal is happy to serve you using our state-of-the-art tools and equipment. We’re a cast metal manufacturing company that supplies caster metals and other products.

Ourexperts are trained and skilled in melting various alloys such as steel,bronze, zinc, stainless steel, and more. Through wide experience and insight,we offer you creative solutions that put your business to high-level status.

Butwait – there’s more we offer.

Whenyou ask about quality cast metals, you’ll find that here in Caster Metal. Weuse advanced technology and our expertise to give you high-quality productsyour business needs. We help you achieve your goals not only through qualityalloys but also fast delivery offers.

Yes,Caster Metal doesn’t give you hassles when it comes to the delivery process.Call us and our experts would schedule the delivery time for you. Expect that you’ll receive your order beforeor on-time.

Also,we offer a budget-friendly approach to our products and services. Ouraffordable items and services assure that you’ll face no hassle in paying forthe items you ordered. We’re happy and proud to introduces some of the moldcasting processes we do – gravity dies casting.

What isGravity Die Casting?

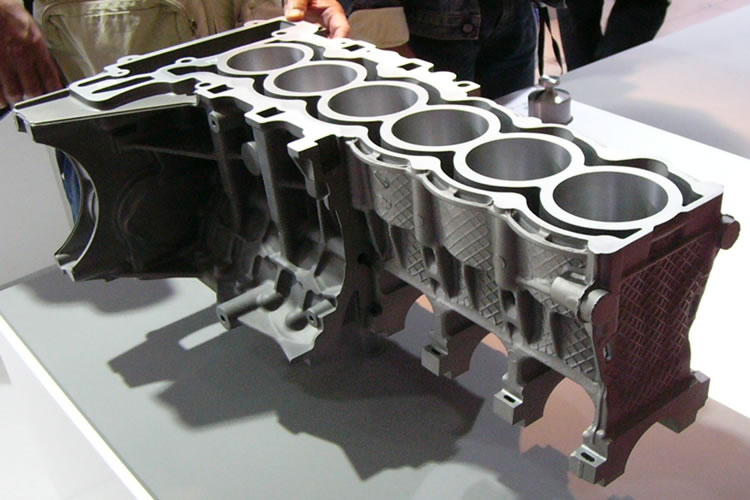

Inthis process, we pour molten metal from a ladle or vessel to the mold. (Themold cavity doesn’t have force besides gravity, so we perform filling bytilting the die.) We use sand cores toincorporate undercuts and cavities to the component form.

Anexcellent surface finish is the result of gravity die casting that’s betterthan sand casting. (The mechanical properties die casting is also better thansand casting. The reason for this is rapid solidification.)

Unlikesand casting, gravity die casting requires less fettling and finishing. Weoffer you high-quality products due to die casting. Also, the gravity diescasting method is less costly than sand casting.

Takenote: gravitydie casting offers a higher casting rate than sand casting. But the metal moldsare a little costly than sand.

OurGravity Die Casting Process

Alright,gravity die casting is a manual method using a ladle. But other high-volumeapplications use an automated ladle in pouring the molten metal. We control thefilling effectively by tilting the die.

Takenote that the gravity die casting process is similar to sand casting and hasfour steps, such as the following:

- We heat the die then sprayed with refractory coating, and we closeit. The coating controls the temperatureof the die effectively. Also, the coating helps in removing the castingseffectively.

- Next, we pour molten metal into the die. (In certain cases, a machineis used to do this process) to solidify the metal.

- Now, we open the die, and we remove the cast parts by hand. (In someconditions, we use ejector pins to opening the die and removing the castparts.)

- Last, we remove the scrap, runners, flash, and sprues from thecastings. Then, we process the castings to remove any sharp edge and extramaterial. If required, we clear the blast.

With gravitydie casting procedure, you’re sure that you achieve satisfaction in yourcasting manufacture. We make sure that we reach your demands when it comes to diecasting. Our experts are open tox suggestions if you want to add your ideas tothe casting process.

We’reproud to give you logical options for die casting such as the following:

- Different non-ferrous materials

- Small to medium size parts

- Excellent surface finish

- Dimensional consistency

- Runs 500 units effectively

CasterMetal offers the best die cast products at a lower price. We ensure thepurchase process for you wouldn’t be a hassle. Our team of engineers is hands-onand willing to exert great effort to finish the work.

Wefollow our engineering values to maximize our supply chain. Caster Metal has ahuge amount of materials and supplies to meet the needs of our clients.

Wewill show you the gravity die casting procedure and ensure that you understandthe process well. Here, we don’t only talk, but we also listen to your productspecifications. So, come now and see what other things we can do here at CasterMetal.

Letinnovation give success to your business!