Exploring the World of Grey Cast Iron: Properties, Production, and Practical Applications

Introduction to Grey Cast Iron

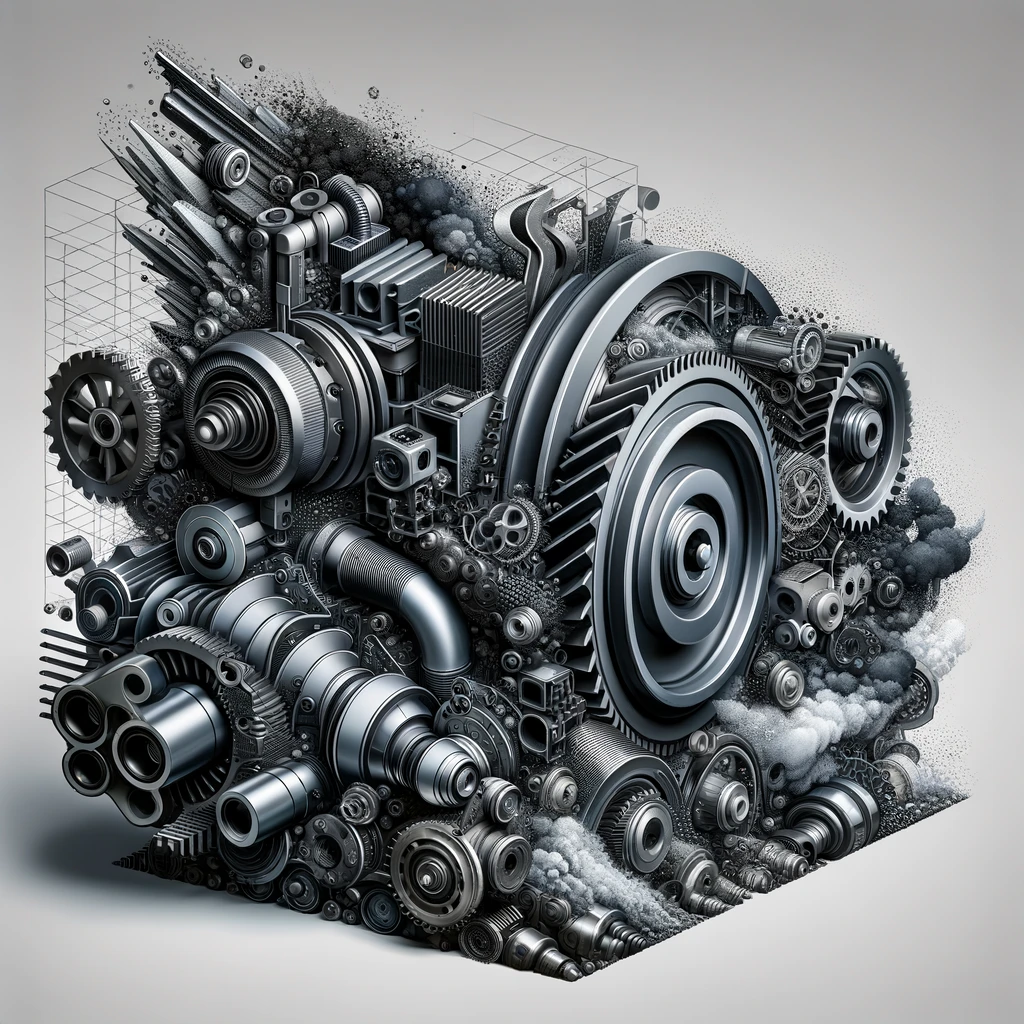

Grey cast iron, a type of ferrous alloy, has been a cornerstone in the manufacturing and engineering sectors due to its remarkable properties and versatility. This material, which contains graphite flakes, is widely used in machinery and automotive parts due to its characteristic grey color.

Historical Evolution of Grey Cast Iron

The history of cast iron dates back centuries, with grey cast iron emerging as a distinct and highly useful material. Its journey from early use in cookware and tools to modern engineering applications is a testament to its adaptability and enduring importance. Over time, the evolution of its composition and production methods has enhanced its qualities and expanded its uses.

Properties and Characteristics

Grey cast iron is renowned for its excellent machinability, good wear resistance, and superb vibration-damping capabilities. It exhibits a unique combination of mechanical properties due to its graphite flake structure, setting it apart from other types of cast iron, like white or ductile iron. These properties make it an ideal choice for applications requiring durability and strength.

Manufacturing Process

- Overview of production: Grey cast iron is produced through a specific melting and casting process, which involves careful control of composition and cooling rates.

- Raw materials: The process begins with selecting high-quality raw materials, including iron ore, scrap steel, and various alloying elements.

- Creating desired shapes involves pouring molten iron into molds using molding and casting techniques. Advances in casting techniques have allowed for more intricate and precise designs.

- Quality control: Rigorous testing and quality control measures ensure the final product meets the required standards and specifications.

Applications and Uses

Grey cast iron finds its applications in several key industries. In the automotive sector, it is used for engine blocks and brake parts due to its ability to withstand high temperatures and pressures. The construction industry utilizes it for pipes and structural components, benefitting from its strength and durability. Its ease of machining also makes it a preferred material for intricate parts in machinery and tools.

Conclusion

In conclusion, grey cast iron is a material of great significance in the engineering and manufacturing world. Its unique properties, historical evolution, and diverse applications underscore its importance. The ongoing developments in its manufacturing process and applications continue solidifying its status as a versatile and indispensable material in modern engineering.

Advancements and Innovations

In the realm of grey cast iron, continuous advancements and innovations have significantly enhanced its capabilities and applications. New alloying techniques have been developed to improve its mechanical properties, making it more suitable for demanding applications. Innovations in production, such as enhanced melting techniques and advanced casting methods, have led to higher quality and more intricate designs. The industry is also exploring using grey cast iron in new fields, indicating a promising future for this versatile material.

Environmental Impact and Sustainability

The production and use of grey cast iron have environmental implications, which the industry is actively addressing. The recycling potential of grey cast iron is a major advantage, as it significantly reduces the need for raw materials and energy consumption. Many manufacturers are adopting more sustainable practices in the production process, such as using recycled materials and implementing energy-efficient technologies. These efforts reduce the carbon footprint and make grey cast iron more environmentally friendly.

Challenges and Limitations

- Brittleness and Crack Sensitivity: Grey cast iron, while durable, is known for its brittleness, especially under tensile stress. This characteristic limits its use in applications where flexibility and elasticity are required.

- Corrosion Resistance: Another challenge is its susceptibility to corrosion, especially in harsh environments. However, advancements in protective coatings and alloying have helped mitigate this issue.

- Overcoming Limitations: Ongoing research and development are focused on overcoming these limitations. Material science and engineering innovations are paving the way for enhanced versions of grey cast iron, broadening its application scope.

Grey cast iron continues to be a material of significant importance in the industrial world. Its unique properties, adaptability, and historical significance make it an invaluable resource in various sectors. The continuous advancements focus on sustainability, and efforts to overcome its limitations are testament to its evolving nature. Grey cast iron will remain a key player in materials engineering as we progress, contributing to innovations and developments in numerous industries.