A Guide to Selecting the Right Stamping Parts Manufacturer for Your Business

Stamping parts manufacturing is a cornerstone of many industries. Selecting the ideal manufacturer is paramount to ensure product quality, timely delivery, and budgetary requirements. This guide sheds light on understanding your business needs, key factors to consider, the significance of a manufacturer’s location, and the importance of sustainability in the stamping parts industry.

1. Understanding Your Business Needs

Before seeking a stamping parts manufacturer, it’s imperative to have a crystal-clear understanding of your business’s needs and how they align with potential manufacturing partners.

1.1. Defining the Scope of Your Project: Scale and Complexity

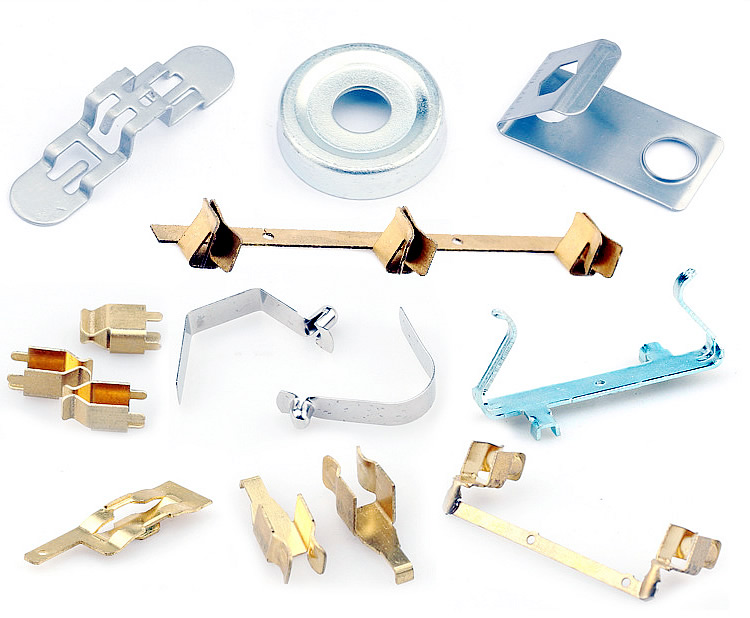

Every manufacturing project varies in scale and complexity. From automotive to electronics and beyond, the specifications change drastically. For instance, while one business might need large quantities of basic stamped components, another might require intricate parts focusing on precision.

- Scale: Determine the volume of parts you’ll need. Manufacturers specializing in large-scale production might not be the best fit for smaller, more bespoke orders and vice versa.

- Complexity: Evaluate the intricacy of the design. Not all manufacturers possess the machinery or expertise to handle exceptionally detailed stamping tasks.

1.2. Recognizing Material Preferences for Specific Applications

Material selection can drastically influence the finished product’s performance, durability, and cost. Aluminum, for instance, is lightweight and offers excellent corrosion resistance, making it suitable for aerospace applications. Meanwhile, stainless steel, known for its strength and resistance to rust, is preferred in automotive and construction applications.

- Performance Needs: Some materials perform better under stress or high temperatures.

- Cost Implications: High-grade materials might elevate the cost but can save money in the long run due to their durability.

1.3. Evaluating Lead Times and Delivery Schedules

Time is often of the essence in manufacturing. Delays in receiving parts can lead to missed deadlines and potential revenue losses. Therefore, it’s crucial to evaluate a manufacturer’s ability to meet your delivery schedules and their track record in adhering to lead times.

2. Key Factors to Consider in a Stamping Parts Manufacturer

Once you’ ‘ve established your needs, it’s time to dive into what makes a stamping parts manufacturer stand out.

2.1. Expertise and Years in the Industry

Experience often equates to expertise in manufacturing. A company with a long history likely has faced and overcome numerous challenges and can offer valuable insights into the stamping process.

2.2. Certifications and Quality Standards Compliance

Certifications, such as ISO 9001, signify a manufacturer’s commitment to quality. Ensure any potential partner complies with international quality standards and other industry-specific certifications. This ensures high-quality products and can be a selling point when marketing your finished goods.

2.3. Equipment and Technology: Staying Ahead of the Curve

Modern challenges require modern solutions. A manufacturer that invests in the latest machinery and technology can offer better precision, faster production rates, and, often, more competitive prices. For instance, a company utilizing 3D printing for prototypes can significantly speed up the design and testing phase.

2.4. Customer Service and Communication: A Collaborative Approach

Effective communication is paramount. The best manufacturers maintain open communication channels, offering regular updates and being receptive to feedback. A collaborative approach can lead to better end products and a smoother manufacturing process.

2.5. Pricing: Balancing Cost and Quality

While cost is always a factor, it’s essential to balance it against quality. Opting for the cheapest option can lead to subpar products, which might result in more significant losses in the long run.

3. The Importance of Location

Geographical considerations can be crucial in the selection process. The location of a manufacturer can impact logistics, costs, and even the quality of raw materials available.

3.1. Proximity to Your Business Operations: The Logistics

Choosing a manufacturer close to your business or your target market can reduce shipping times and costs. This is especially crucial for businesses operating on just-in-time production schedules.

3.2. Geopolitical Stability and Its Impact on Supply Chains

Manufacturing in regions prone to political unrest can disrupt supply chains. Always consider a manufacturer’s political and economic stability ‘s location.

3.3. Local Regulations and Their Influence on Manufacturing Processes

Environmental and safety regulations can vary widely between regions. Ensure that any potential manufacturer adheres to all local laws, which can also impact product quality and safety.

4. Exploring Sustainability Practices

In today’s market, sustainability isn’t just a buzzword; it’s often a business imperative. An increasing number of consumers are considering the environmental impact of their purchases, meaning businesses should prioritize sustainable practices.

4.1. Environmentally-friendly Manufacturing Processes

Seek out manufacturers that utilize green technologies and energy-efficient machinery. This not only reduces the environmental footprint but can also result in cost savings.

4.2. Sustainable Sourcing of Materials

Raw materials play a significant role in a product’s environmental impact. Opt for manufacturers that source sustainably-produced or recycled materials.

4.3. Waste Management and Recycling Initiatives

A forward-thinking manufacturer will have robust waste management and recycling protocols, ensuring minimal environmental harm and possibly reducing production costs.

5. Case Studies: Success and Cautionary Tales

Real-world experiences often offer the best insights into the challenges and triumphs of selecting a stamping parts manufacturer. Let’s delve into some illustrative case studies.

5.1. Businesses that Thrived with the Right Manufacturer

Case Study: AlphaTech Inc.

AlphaTech, a startup in the electronics sector, was keen on launching a new line of premium smart devices. They partnered with StampingElite, a manufacturer with a stellar reputation for precision and timely deliveries. The collaboration succeeded in launching a high-quality product line within the projected timelines. AlphaTech saw a 50% increase in sales, largely attributed to the impeccable build quality of their devices.

5.2. Lessons Learned from Wrong Choices

Case Study: BetaMotors Corp.

BetaMotors, an emerging name in the automotive industry, aimed to produce affordable electric cars for the middle market. To cut costs, they partnered with a less-experienced stamping manufacturer. This decision led to several setbacks, from subpar battery casings to frequent delays. BetaMotors had to recall several units, incurring significant losses and tarnishing their brand reputation.

5.3. Adapting and Pivoting in the Face of Manufacturing Challenges

Case Study: GammaWear Co.

GammaWear, a sportswear brand, initially faced challenges with their manufacturer due to inconsistent fabric stamping quality. Instead of severing ties, they collaborated closely with their manufacturer to identify the issues. They introduced quality control measures and training sessions with mutual effort, turning potential failure into a partnership success story.

6. The Evaluation Process: Steps to Shortlisting Manufacturers

Selecting a manufacturer isn’t a decision made in haste. It’s a meticulous process of evaluation and re-evaluation until you find the perfect fit.

6.1. Gathering Recommendations and Doing Market Research

Start by reaching out to industry peers for recommendations. Online platforms, like industry forums and LinkedIn groups, can also offer insights. Please take note of manufacturers that are consistently mentioned for their quality and reliability.

6.2. Conducting Initial Interviews and Factory Tours

Once you have a shortlist, set up interviews with potential manufacturers. This gives an understanding of their capabilities, machinery, and work ethic. Conduct factory tours to get a firsthand look at their operations.

6.3. Asking for and Assessing Samples

Always request samples. This provides a tangible sense of the manufacturer’s capabilities and the expected quality. Compare these samples with your product specifications to ensure alignment.

6.4. Reviewing Contracts and Negotiation Tips

Once you’re nearing a decision, it’s time to discuss contracts. Ensure clarity on terms, especially regarding quality standards, delivery timelines, and payment structures. Don’t hesitate to negotiate; manufacturers often leave room for flexibility, especially if they see the potential for a long-term partnership.

7. Future-Proofing Your Collaboration

Establishing a relationship with a manufacturer is just the beginning. The business landscape evolves, and so should your collaboration.

7.1. Regular Reviews and Feedback Loops

Hold regular review meetings to discuss performance, challenges, and future needs. This proactive approach ensures both parties are aligned and can adapt to changing circumstances.

7.2. Adapting to Market Changes and Technological Advancements

Stay updated with industry trends and technological advancements. Encourage your manufacturer to adopt new technologies or processes to enhance product quality or reduce costs.

7.3. Nurturing the Relationship for Long-Term Partnership

Like any partnership, the relationship with your manufacturer needs nurturing. Regular communication, understanding challenges from their perspective, and celebrating mutual successes can go a long way in fortifying the relationship.

Choosing the ideal stamping parts manufacturer is more than finding someone to produce components; it’s about forging a partnership that stands the test of time. This collaboration can significantly influence your product’s quality, brand’s reputation, and bottom line. By meticulously understanding your needs, evaluating potential partners, learning from others’ experiences, and nurturing the relationship, you set the stage for a successful, long-lasting collaboration. May this guide serve as a roadmap, leading you to fruitful partnerships and unparalleled success in stamping parts manufacturing.